Sinopec took the initiative in promoting the construction of the responsibility industry chain, insisted in the responsible and transparent procurement, optimized the management of suppliers and contractors, augmented the strategic cooperation, supported the development of national industry, and drove the sustainable development of upstream and downstream industry chains, to attain mutual benefits and win-win results with partners.

Supplier management

Sinopec provided equal opportunities for suppliers, continuous optimized supplier management system and business procedures, prevented supply chain risks, and created a transparent, sound and honest material supply ecosystem with suppliers.

Examine supplier qualification strictly

Following the principle of combining pre-qualification and post-qualification, Sinopec implemented the examination of supplier qualification strictly and conducted on-site examination for suppliers who participated in business for the first time and who experienced great changes in operation and finance, as well as examined the supplier qualification based on their factories, equipment, products, management, and performance. In 2020, Sinopec organized on-site examination for 1187 suppliers, trying to prevent and control supply risks from the source.

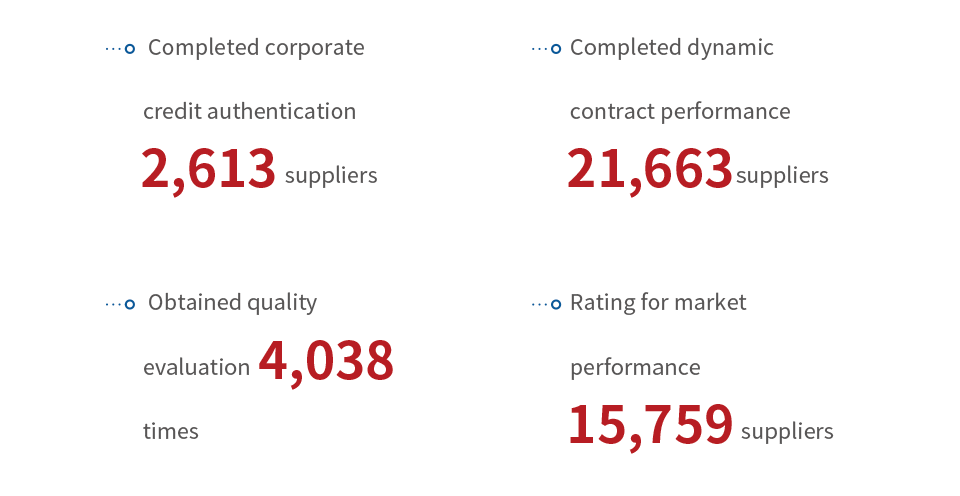

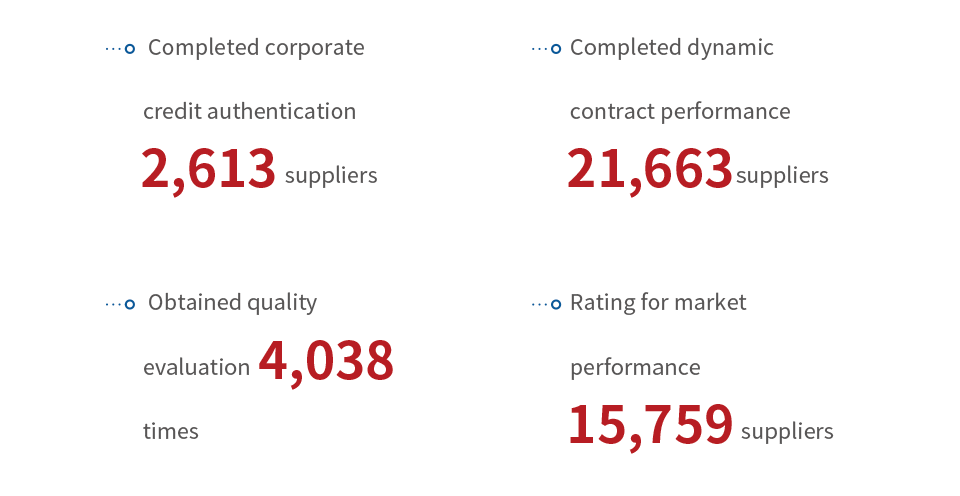

Implement quantitative evaluation for suppliers

We evaluated and portrayed suppliers in an integrated and accurate manner based on the EPEC standards (ES) to give an all-round and objective assessment of suppliers' comprehensive strength. We displayed the ES data board in real-time on the EPEC platform and considered the data on ES in bidding and procurement for promoting suppliers to enhance quality and efficiency and creating a new business ecosystem with quality as the top priority. In 2020, a total of 2613 suppliers completed the corporate credit authentication; a total of 1242 suppliers obtained 4038 product quality evaluations; a total of 21,663 suppliers finished the dynamic assessment for contract fulfillment; a total of 15,759 suppliers completed the rating for market performance.

Persist in green procurement

Sinopec established a long-term mechanism for green procurement management, added performance evaluation indexes, such as energy-saving, environmental protection, and low carbon, improved the quantitative evaluation of green procurement, strengthened the qualification examination with respect to environmental protection, health and safety, guided suppliers to perform their social responsibilities of environmental protection and resource conservation, encouraged suppliers to develop green technologies and products, and prohibited to purchase products listed in the directory of products with "high pollution and high environmental risks."

Establish and improve the incentive mechanism for keeping promises and the punishment mechanism for breaking promises

We sent reminder letters to 142 suppliers who have signs of problems in quality, schedule, and bidding to nip supply risks in the bud. Besides, we had on-site interviews with suppliers who delivered products and services with poor quality to urge them to enhance the quality of supply service. The Group punished suppliers with acts of breach of contract, dishonest conducts, and incorruptible conducts to urge them to carry out integrity and regulated operations. In 2020, Sinopec punished and publicly reported 41 suppliers who had acts of breach of contract to build a supply ecosystem emphasizing quality, service, brand, and word-of-mouth.

Strengthen the training for suppliers

We organized training, symposiums, and bid clarification meetings for suppliers, publicized and conveyed Sinopec's material procurement concept and bidding management system to suppliers, introduced core values and cooperation models of EPEC platform (www.epec.com). In 2020, Sinopec held supplier training six times, involving more than 670 persons.

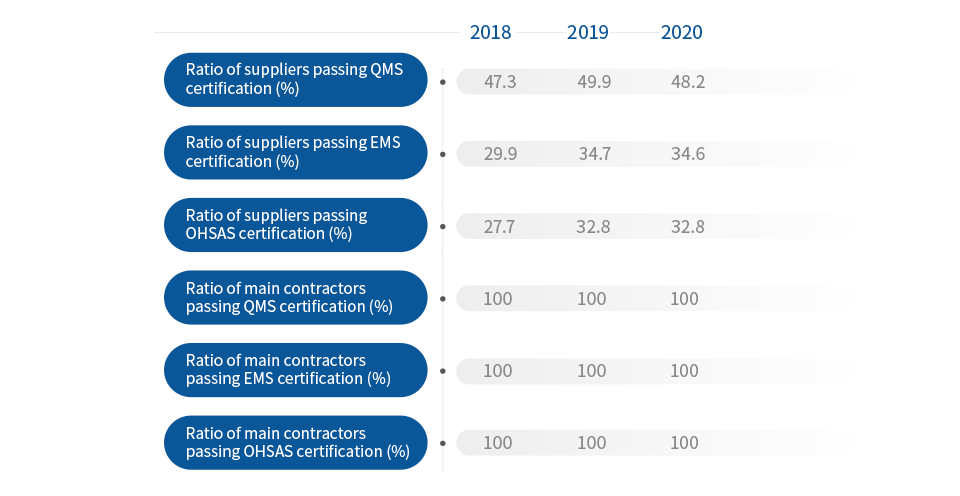

Contractor management

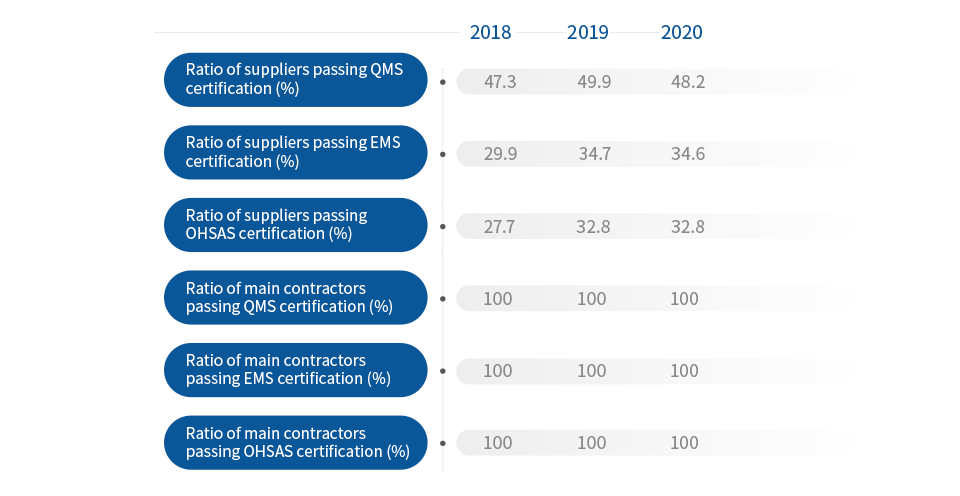

Sinopec adhered to the management principles of openness, fairness, integrity, and good faith to realize transparent engineering procurement. Moreover, Sinopec implemented assessment management for contractors, registered contractors in database, and strengthened the examination of contractors' basic information, such as business licenses, qualification documents, and certificates for OHSAS certification, EMS certification, and QMS certification. Per the HSSE management requirements, Sinopec set up bidding qualifications for contractors according to law and prohibited fraudulent contractors from participating in bidding. Moreover, Sinopec established a contractor management information platform on which contractors and subcontractors were subject to online assessment, and adverse issues of contractors and their employees could be found and recorded in time to realize instant assessment and treatment.

Drive the development of industrial chain

Keep the business operation of EPEC platform

Based on the EPEC e-commerce platform, Sinopec innovated new SC2B e-commerce model of "Internet + supply chain" following the concept of "making procurement more professional" to provide core business covering procurement, sales, finance, and comprehensive field for enterprises. EPEC, as a one-stop service platform, focused on serving enterprises while making innovations and exploring practices. It has built a service matrix comprising "E-pay," "E-trip," "E-insurance," "E-authentication," "E-bill Manager," "E-logistics," and "E-life", providing ecological services focusing on supply chain value-added services for the platform members.

By the end of 2020, transactions amounting to RMB 1.42 trillion were completed on EPEC, and 239,000 registered users from 104 countries and regions traded 18.98 million items of 2.91 million categories on the platform. In 2020, the platform was listed as the pilot demonstration project for big data industry development of 2020 by the Ministry of Industry and Information Technology.

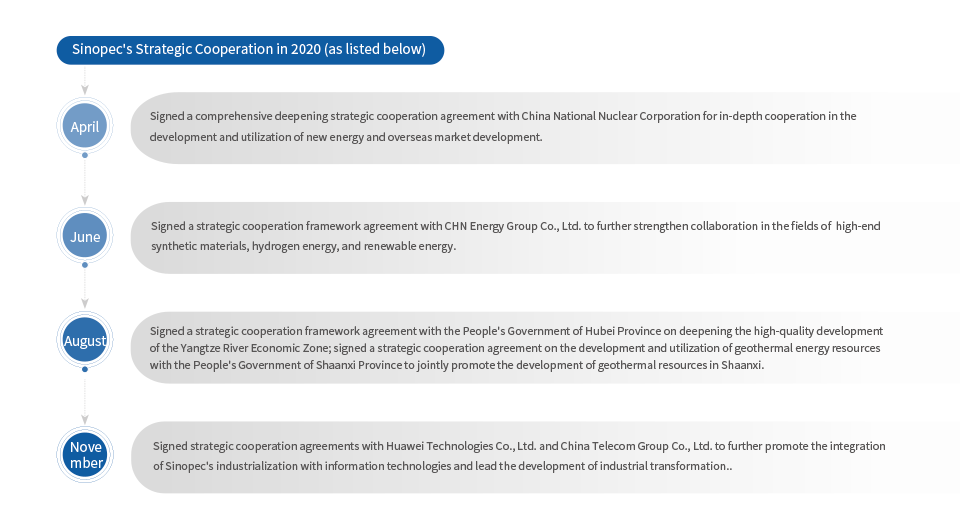

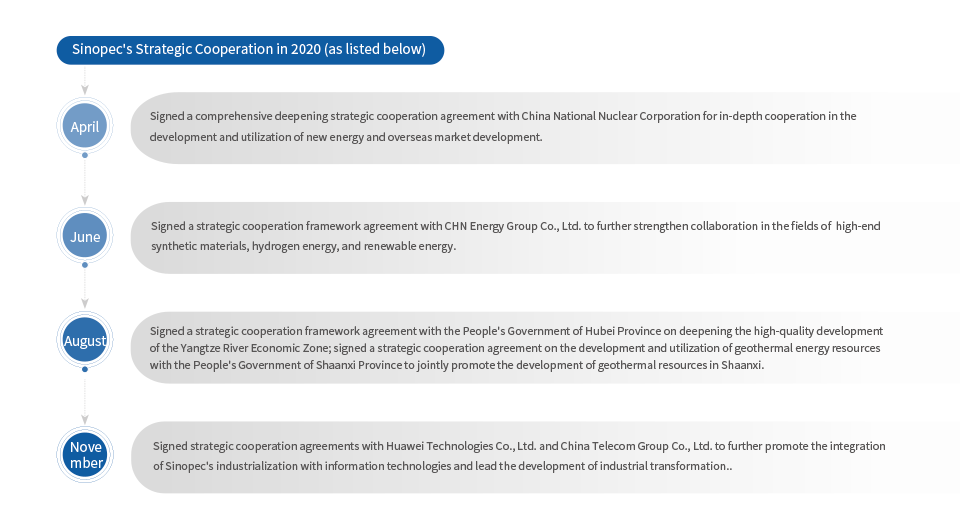

Strengthen strategic cooperation

Sinopec carried out strategic cooperation with government and enterprises with great effort to attain mutual benefits and win-win results.

Sinopec signed purchase agreements with 50 overseas suppliers from 15 countries and regions at the 3rd China International Import Expo, with a trading volume of over USD 32.5 billion

Reinvigorate national industry

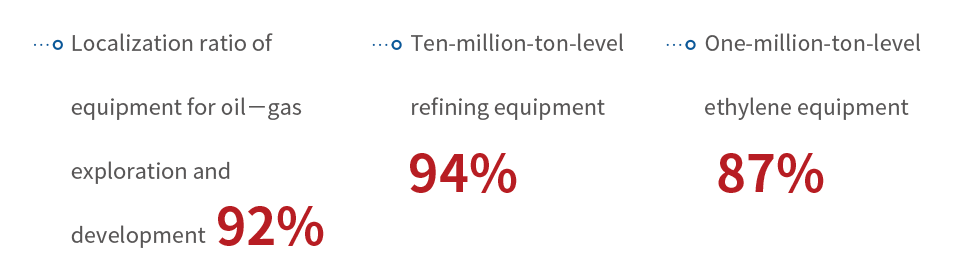

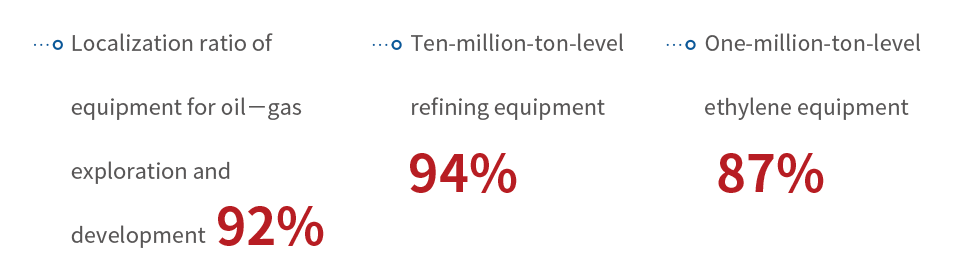

Acting upon the guiding principles from General Secretary Xi Jinping’s major speeches, Sinopec led the world's benchmarks while maintaining safety and put more efforts on the localization of major equipment through independent R&D and collaborative R&D with domestic enterprises.

At the end of the 13th Five-Year Plan, Sinopec achieved the localization of major equipment, setting a new record for the localization ratio of major equipment. It also further enhanced the self-control ability for industry chain and supply chain, making major contributions to the development of the petrochemical industry and the transformation and upgrading of China's equipment manufacturing industry. Particularly, the localization ratio of equipment for oil-gas exploration and development reached up to 92%, ten-million-ton-level refining equipment up to 94%, and one-million-ton-level ethylene equipment up to 87%.

Over the years, Sinopec's localization of major equipment has always been staying ahead of central SOEs. Zero breakthroughs have been attained in terms of the localization of major equipment such as fracturing units, truck-mounted drilling rigs, double-coating special pipes for petroleum geology in the field of petroleum exploration and development, as well as reactors, compressors, heat exchangers, and decentralized control systems (DCS) in the refining and chemical field, which markedly reduced the procurement cost and shortened the manufacturing cycle. Ethylene cracking furnace, as the most crucial equipment in the ethylene industry, has realized the transition from import to export.

Address

Address Post code

Post code Tel

Tel 川公網安備11000132213211

川公網安備11000132213211