Sinopec integrated climate change into its development plan, continuously improved energy management, did a good job in decreasing greenhouse gas emission, and established a new image of "clean, low-carbon, and industry-leading."

Improvement in energy efficiency

Sinopec continued to implement the "energy efficiency improvement" plan and strictly performed the "double-control" over total energy consumption and energy consumption intensity. Using means such as the energy conservation based on management technology, the utilization of new energy, and the smart construction, Sinopec saved energy and resources, improved energy utilization rate, and injected "green power" into the development of the enterprise. In 2020, 559 "energy efficiency improvement" projects were implemented, saving energy 1.01 million tons of standard coal equivalent that year.

The "double-control" over total energy consumption and energy consumption intensity

We tightened the "double-control." We signed the annual energy and environment responsibility statement with the business division and enterprises to reinforce the management of total energy consumption, process inspection, and early warning. Moreover, we gave quarterly reviews and annual assessment.

We improved the internal and external reviews of the energy management system. Thus, we organized several rounds of systematic training for key energy consuming units.

We performed energy auditing and energy conservation supervision to address the reckless energy use in enterprises and enhance the energy conservation management in enterprises to promote the effective operation of the energy management system.

We assessed the efficiency of energy conservation for fixed-asset investment projects to urge enterprises to do a good job in the demonstration of the feasibility study report on energy conservation, as well as the elementary design review and the evaluation and acceptance. We aimed resolutely to control the growth of energy consumption at its source.

We conducted energy-saving inspection. We inspected the energy utilization of large units and major power equipment in refining and chemical enterprises, as well as that of water injection system, mechanical extraction system and gathering and transportation system in oil field enterprises to explore their energy-saving potential.

The imitation in depth

The energy efficiency "frontrunner" campaign was launched. Externally, advanced enterprises were recommended to participate in the energy efficiency "frontrunner" event organized by national ministries and commissions and industry associations so that these enterprises could serve as first-class role models for others to follow. Internally, we deepened inter-enterprise and inter-plant imitation. All business units increased the weight of energy efficiency index assessment to further conduct competitive activities, including the "follow and surpass" and "make the plant meet the standards."

Greater efforts for R&D and promotion of energy-saving technologies

We organized segments including the oil field, refining and chemistry, and oil product sales to analyze which energy-saving technologies were mature and applicable to perform in-depth promotion.

We independently developed the green and efficient complete technology for megaton ethylene plant and the large-scale, high-efficiency, and energy-saving complete technology for aromatics plant to attain essential energy conservation.

Progress in the utilization of new energy

We made great efforts to promote the use of the waste heat of oil production wastewater, as well as the geothermal and solar energy, to attain a clean energy structure. By 2020, 38 enterprises had executed 230 new energy projects on the utilization of the waste heat of oil production wastewater, as well as the geothermal and solar energy, replacing 1.214 million tons of standard coal equivalent. A total of 21 enterprises planned to implement 36 new energy projects, which were expected to replace 208,700 tons of standard coal equivalent.

Information construction for energy management

We promoted the digital transformation and intelligent development of energy management in an orderly manner. Based on the new mode of "data + platform + application" and with the goal of "maximizing energy efficiency, visualizing energy flow and optimizing online," we actively executed the construction of energy management information systems for 37 refining and chemical enterprises and created a cumulative driving force optimization benefit equivalent to over RMB 100 million.

Management of greenhouse gas emission

Sinopec resolutely implemented the new development concept and worked actively to control greenhouse gas emission; therefore, we made significant progress in reducing carbon emission.

Carbon dioxide flooding

Oil field enterprises performed carbon dioxide flooding in an orderly manner, injecting 298,000 tons of carbon dioxide and increasing oil production by 43,000 tons.

Carbon dioxide recycling

Refining and chemical enterprises recycled 1.29 million tons of high-concentration carbon dioxide emitted by hydrogen manufacturing and synthetic ammonia plants.

Methane emission Reduction

Oil field enterprises promoted the technique of "simultaneous gas gathering and testing" and strengthened the recovery measures of remote and scattered oil wells, which recovered about 600 million cubic meters of methane and decreased greenhouse gas emission by about 9 million tons of carbon dioxide equivalent.

Refining and chemical enterprises continued to optimize the operation and management of biogas transmission and firing projects from biochemical equipment, which enhanced the utilization efficiency of biogas and recycled 12.86 million cubic meters of biogas that year.

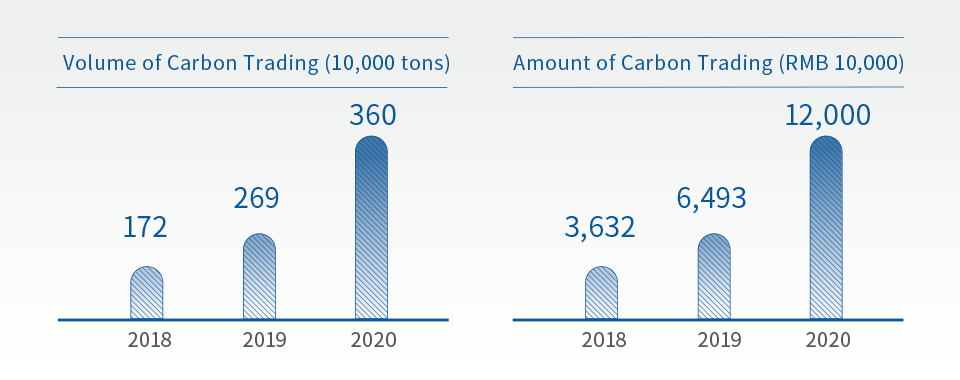

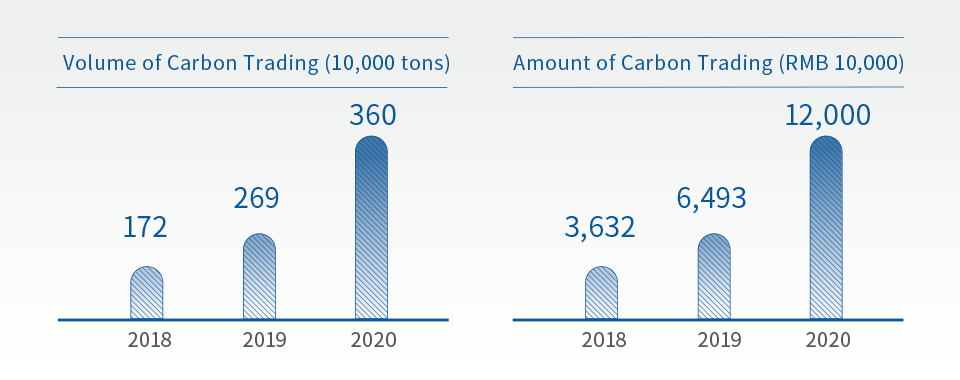

Carbon assets management

We continued to make efforts to check and validate carbon emissions, strengthened greenhouse gas emission reduction assessment, researched to identify carbon footprint accounting and evaluation methods, and enhanced the carbon labeling system for Sinopec products.

A total of 26 pilot carbon trading enterprises formulated reasonable implementation plans and trading plans to actively leverage the Chinese Certified Emission Reduction (CCER) scheme that compensates carbon emission quotas to decrease implementation costs and implement the annual carbon quota on time.

We systematically analyzed the existing defects of the carbon emission management information system and the business requirements in the national carbon market. Besides, we worked actively to promote the comprehensive upgrade of the carbon emission information system and supported the company's response to the national carbon market and the tasks for peak carbon dioxide emission and carbon neutrality.

Enhanced international exchanges

Sinopec strengthened international exchanges and cooperation as it joined international organizations like the United Nations Global Compact, the World Business Council for Sustainable Development (WBCSD), and the Alliance To End Plastic Waste (AEPW) to collaborate to combat climate change and contribute to eliminate plastic waste from the environment.

Address

Address Post code

Post code Tel

Tel 川公網安備11000132213211

川公網安備11000132213211